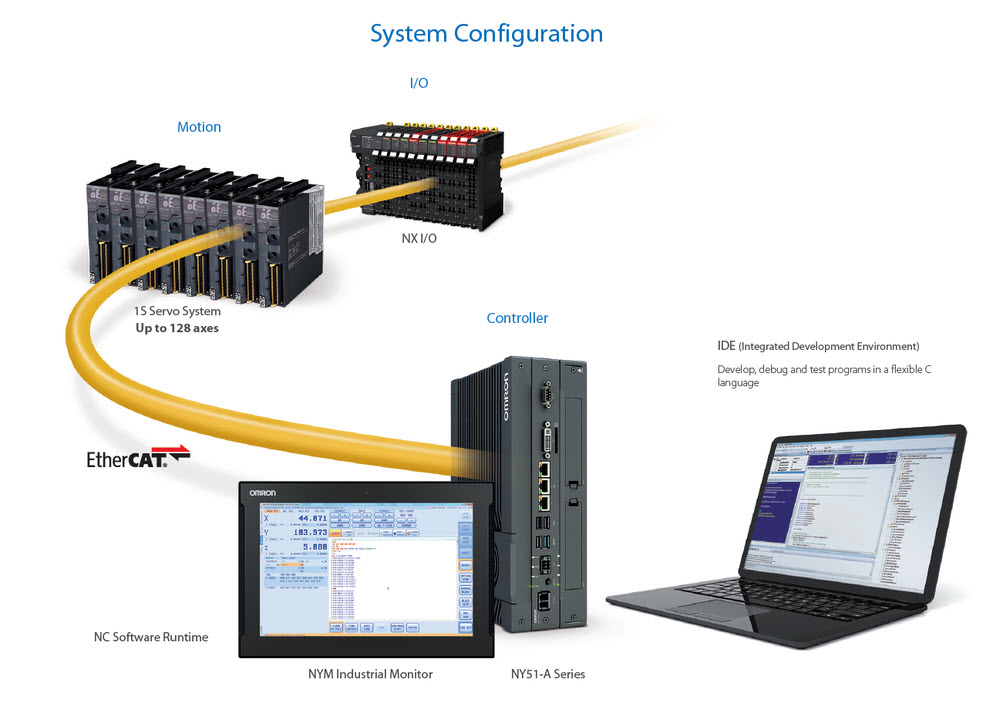

The NY series of IPC brings industrial strength computing to the factory floor. Screen sizes, CPU, memory, operating systems and hard drive options for the most demanding factory floor applications such as SCADA, ERP/SAP, SQL. As part of the Sysmac Solution of products, an optional QNX Real-Time Operating system is available running embedded NJ Machine Automation technology on EtherCat to the NX I/O system for IPC based control.

Overview

IPC Programmable Multi Axis Controller

- Intel® Core™ i7-4700EQ processor with fan for active cooling

- 128 axes motion control

- Up to 250 μs cycle time

- Flexible function development capability (G-Code/ANSI C/original programming language)

- Multi-tasking of Motion Control and Windows applications

- Hypervisor allows to continue to control even if OS crashes

Complex kinematics

Complex mechanics can be controlled thanks to the matrix handling and the space conversion. Special applications like Hexapod telescope mirror positioning, can be easyly operated by the kinematics handling functionality.

Leveraging features for accurate machining application

G-Code

![]()

Standard RS-274 G-Code interpreter. User-writable subroutines for customized implementation of G, M, T and D-codes. Flexibility to adapt the syntax and to work in combination with any CAD/CAM software.

Cutter compensation 2D/3D

![]()

Tool diameter and shape compensation, matching the cutting point exactly as specified in G-Code.

Fast processor + large program buffer

![]()

Fast processor can handle over 10,000 blocks per second and up to 1Gb part programs.

Block Retrace for reversing the path

![]()

Path can be reverted in order to remove the tool from cutting area.

Advanced Block Lookahead

![]()

Instructions in the buffer are analyzed in advance, movements are blended and optimized in speed and acceleration for a better performance.

Tangent tool management

![]()

Tools with a cutting direction require a tangent path positioning.

IPC Machine Controller

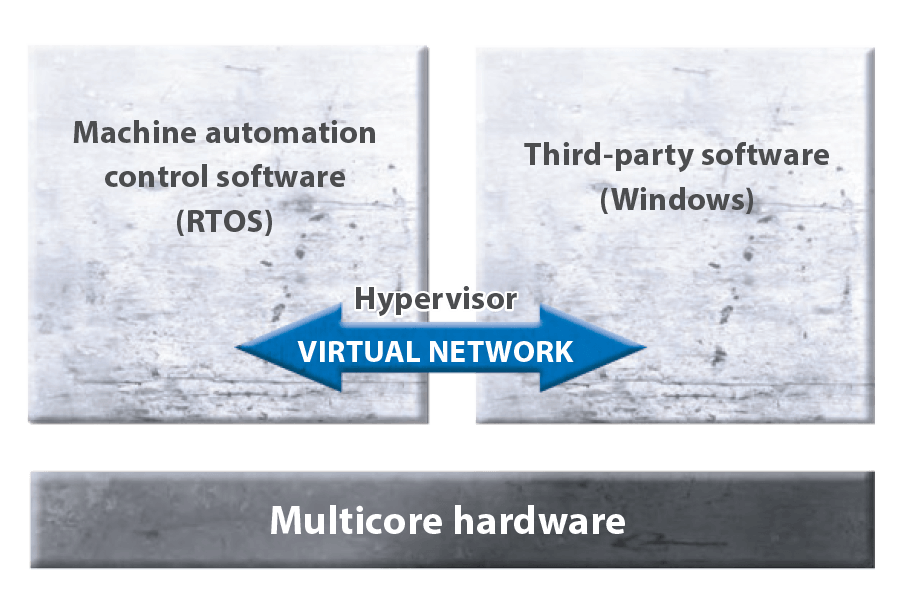

Hybrid controller which combines Sysmac machine control and IT technology

- Intel Core i7 Quad-core processor

- Windows Embedded Standard 7 64-bit

- Open operating system allows running customised software and hardware

- Built-in EtherNet/IP port for your IT systems and machine to machine communication

- Sysmac machine controller inside

- 500 μs system cycle time

- Up to 64 synchronized axes

- Built-in EtherCAT port for up to 192 synchronized slaves

The beating heart of the IPC machine controller

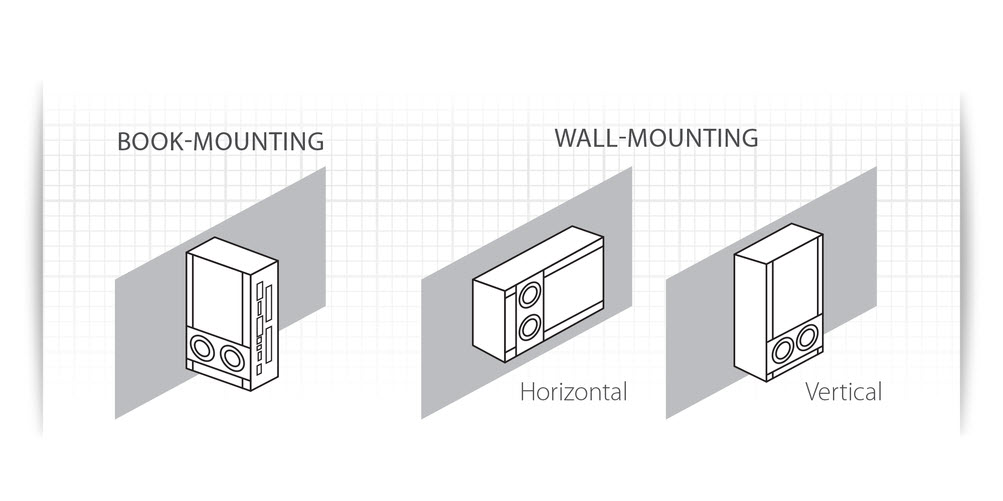

Industrial Box PC – versatile installation

A few details...

- 12.1 & 15.4 Inch industrial display

- Multi-touch, using the latest projected capacitive technology

- False touch detection

- Glove operation

- Easy built-in supportive mounting

Connections

- Options: RS-232C or extra DVI-D for dual monitor

- DVI -3x RJ45 Gigabit Ethernet ports -2x USB2.0, 2x USB3.0

- Choice of storages devices: HDD or SSD (MLC and long-life SLC types) Second drive option

- I/O connection prepared for UPS connection -Power supply: 24VDC non-isolated

NY5 IPC Machine Controller with AI Machine Learning Functionality

The AI Controller version of the NY5 IPC Machine Controller allows for data collection, analysis, and utilization completely for the purpose of high-speed and high-accuracy Anomaly Detection. This functionality is designed to extend equipment life and utilization, as well as help manufacturers improve production quality. By implementing AI on the Edge, without Fog or Cloud connectivity, manufacturers avoid additional infrastructure and maintenance costs associated with off-premises solutions, also protecting their data security.

- Ideal for detecting mechatronic issues and correcting them

- Highest data collection speed and security with integrated Time Series Database

- Data collection cycle (min. 125µs) synchronized with machine control cycle for immediate response

- Sysmac Libraries available for AI Predictive Maintenance

- Start-up support and training by Omron engineer

- Simplified feature extraction and model creation

- Programmed using Sysmac Studio software